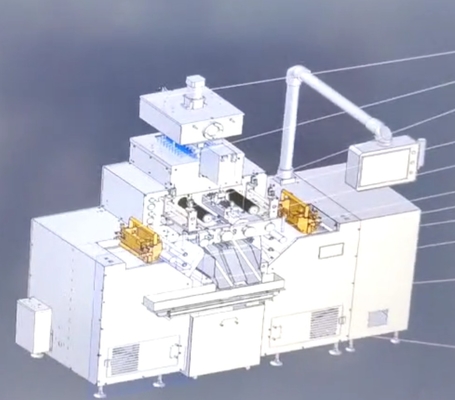

Product Description:

Our soft gel capsule machine for sale is constructed from durable stainless steel, ensuring that it can withstand even the toughest manufacturing environments. The casting drum is even coated with chrome for added durability and longevity.

With a capacity of up to 100,000 capsules per hour, our soft gelatin encapsulation machine is perfect for large-scale manufacturing operations. And with an external chiller providing cooling for the casting drum, you can rest assured that your capsules will be produced to the highest standards of quality.

But that's not all - our soft gel capsule machine also features a diaphragm pump with external circulation, ensuring that the filling pump is always properly lubricated and ready to go. This helps to reduce downtime and increase overall productivity.

Investing in our rolling type soft capsule machine is a smart choice for any manufacturer looking to increase efficiency and output while maintaining the highest levels of quality. Contact us today to learn more about how our soft gel capsule manufacturing equipment can benefit your business.

Features:

- Product Name: Rolling Type Soft Capsule Machine

- Capacity: 100,000 Capsules/hour

- Cooling for Casting Drum: External Chiller

- Die Roll Size: Ф150x50mm

- Rolling Speed: 1-3.5rpm

- Plunge: 1.5mL(±1.5%)

This soft capsule machine, also known as a soft gelatin capsule filling machine, has a capacity of 100,000 capsules per hour. It features an external chiller for cooling the casting drum and has a die roll size of Ф150x50mm. The rolling speed of this soft capsule machine is adjustable from 1-3.5rpm and the plunge is 1.5mL(±1.5%).

Technical Parameters:

| Product Name |

Rolling Type Soft Capsule Machine |

| Power Supply |

380V/50Hz |

| Rolling Speed |

1-3.5rpm |

| Yield |

6120 Grains Per Hour@1.5 RPM (8 # Ov); 2970 Grains Per Hour@1.5 RPM (20 # OB) |

| Lubrication for Gelatin Ribbon |

Independent Metering Pump |

| Cooling for Casting Drum |

External Chiller |

| Material |

Stainless Steel |

| Die Roll Speed |

1-3.5rpm |

| Casting Drum |

Stainless Steel Chrome Coating |

| Capacity |

100,000 Capsules/hour |

| Filling Precision |

≤±3% |

Applications:

The soft gel capsule making machine is suitable for use in the pharmaceutical, food, and cosmetic industries. Its filling precision of ≤±3% ensures that each capsule is filled accurately, which is crucial in ensuring the quality and consistency of the products. The machine's die roll speed of 1-3.5rpm and rolling speed of 1-3.5rpm make it easy to produce up to 100,000 capsules per hour, which is ideal for high-volume production requirements.

The soft gelatin capsule filling machine is also versatile, as it can be used to produce capsules of different sizes and shapes. It offers a yield of 6120 grains per hour at 1.5 RPM (8 # Ov) and 2970 grains per hour at 1.5 RPM (20 # OB), which makes it easy to produce soft gel capsules of different types and sizes to meet specific customer needs.

The Rolling Type Soft Capsule Machine is ideal for use in various scenarios, including the manufacture of dietary supplements, vitamins, and other health products. It can also be used in the production of cosmetic products such as skincare and hair care products. With its high production capacity and accuracy, the machine is perfect for use in large-scale manufacturing operations.

Support and Services:

Our Rolling Type Soft Capsule Machine offers the following technical support and services:

- Installation and setup assistance

- Operator training

- Maintenance and repair services

- Replacement parts and accessories

- Technical troubleshooting and support

We are committed to ensuring that our customers receive the best possible support and service for their Rolling Type Soft Capsule Machine. If you have any questions or concerns, please do not hesitate to contact us.

FAQ:

Q: What is the brand name of the soft capsule machine?

A: The brand name of the soft capsule machine is TIENMIN.

Q: Where is this soft capsule machine manufactured?

A: The soft capsule machine is manufactured in China, the place of origin.

Q: What is the capacity of the machine?

A: The capacity of the machine is determined by the model you choose. Please refer to the product specifications for more details.

Q: Is the machine easy to operate?

A: Yes, the machine is designed for easy operation. We provide detailed instructions and training for our customers.

Q: Does the machine come with a warranty?

A: Yes, the machine comes with a warranty. Please refer to the warranty information provided with the product for more details.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!